Maintenance Strategy

Maintenance Strategy is the foundation in the high reliability organisation, where all identified high risk failure modes are prevented by time or condition based strategy.

Maintenance Strategy is the foundation in the high reliability organisation, where all identified high risk failure modes are prevented by time or condition based strategy.

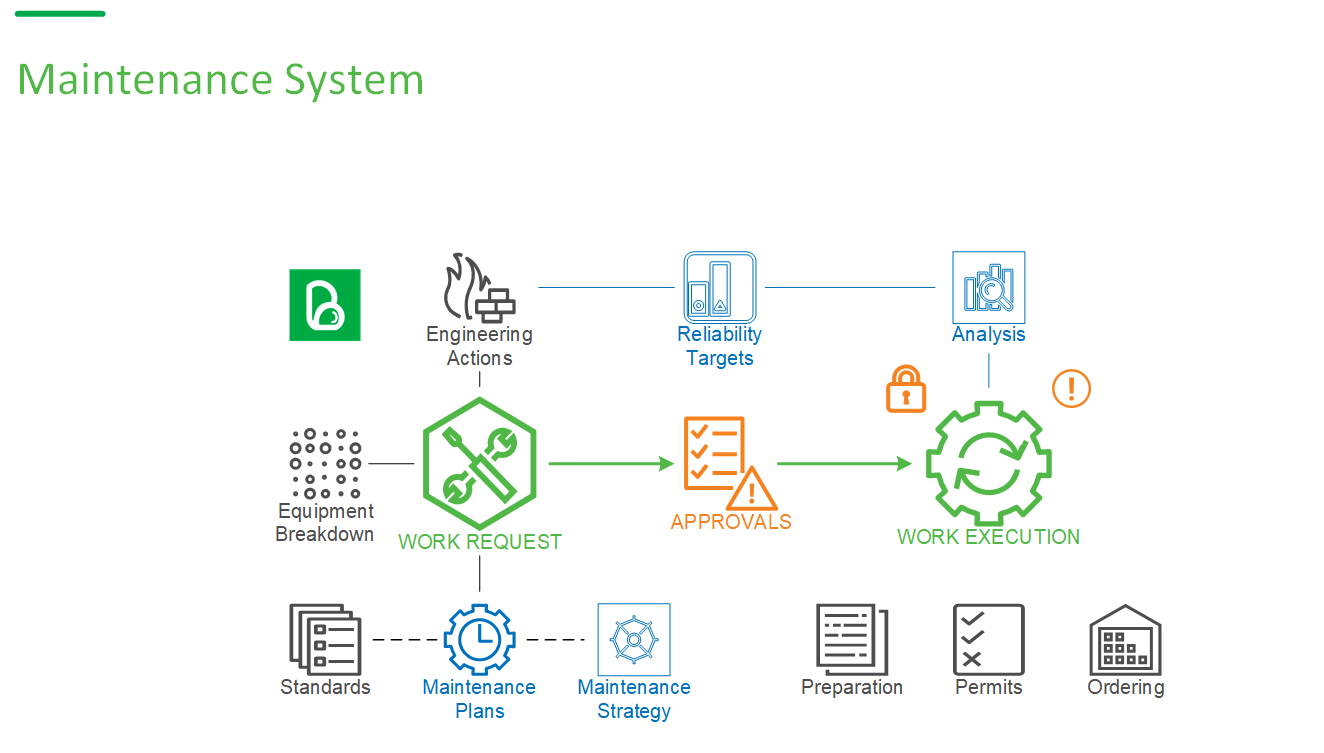

Besea Maintenance system delivers total lifecycle facility maintenance solution from Maintenance Strategy to planning, resourcing and execution of Work Request.

Besea Technical Change System provide complete solution to manage site mods and deviations, equipment upgrades, approvals and risk assessment.